The Vector loading accuracy indicates how precisely the system loads the requested feedstuff. Or in other words, it represents how close the loaded feed (that ended up in the MFR bin) was to the requested feed. Loading accuracy is an important indicator for the functioning of the system. The higher the loading accuracy, the more precise the feed is loaded and the better you know what is being fed to your cows! It’s important to note that accurately loading the ration can result in a longer loading time. It’s therefore a matter of finding a good balance between loading accuracy and system free time.

The Vector loading accuracy widget shows how accurately the Vector system loads rations. Loading accuracy depends on:

Feedstuff shape and related loading properties;Loading method (e.g., auger vs feed grabber);

The accuracy can differ per feedstuff, as some are loaded by an auger and some by the feed grabber and they have their own loading properties. For example, the feedstuff grabber settings can have a major impact on the loading accuracy of the feed grabber, see Feedstuff Vector. On the other end, the accuracy of the augers can be influenced by the settings on the PDB / Feed controller.

How to add the widget

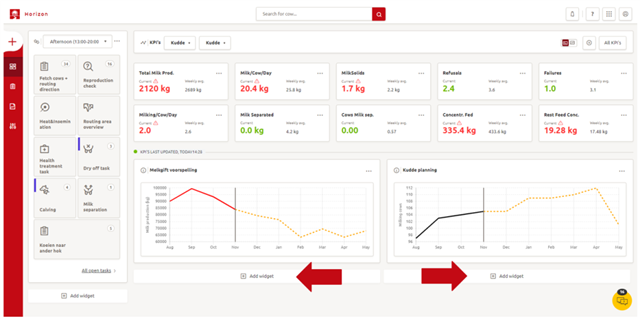

Step 1: the Loading accuracy widget can be added to the dashboard by clicking on ‘Add widget’.

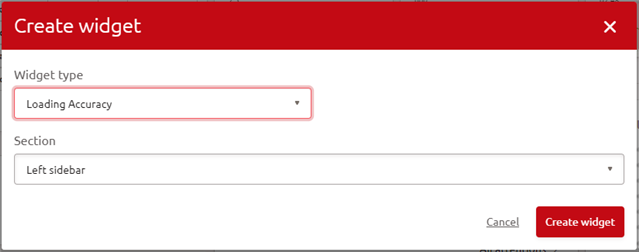

Step 2: select ‘Loading accuracy’ as the widget type in the pop-up screen. Select the dashboard section where you want the widget to appear (‘left sidebar’ or ‘main’). The average of the loading accuracy of the whole ration shown over 5 (left sidebar) or 7 days (main). Click on ‘Create widget’.

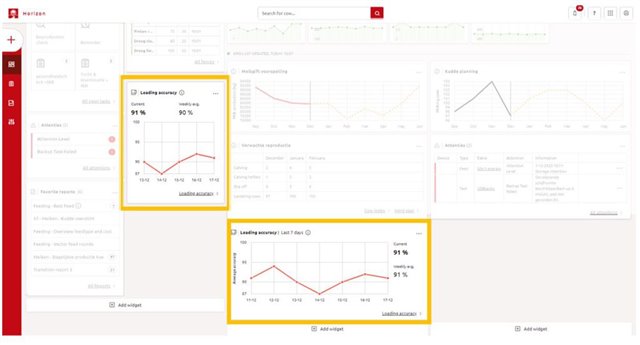

Step 3: The widget then comes available on the dashboard and has a click-through fur further analysis.

How to use the information

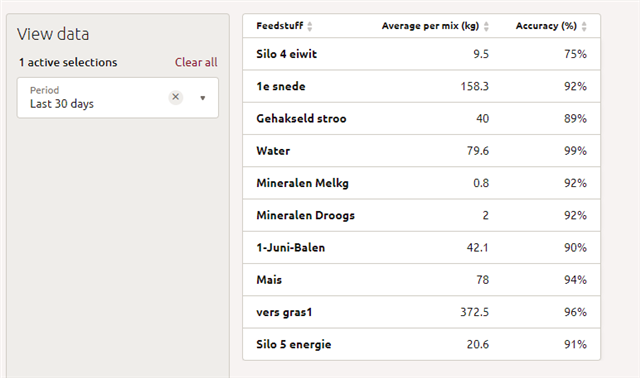

The accuracy information is shown per feedstuff and can be shown at three levels, ‘Yesterday’, ‘Last 7 days’ or ‘Last 30 days’. There is also an ‘Average per mix’ column, which should help estimate the impact of the accuracy of a specific feedstuff on the total rations of cows.

Average accuracy per feed type

Several factors can directly affect loading accuracy, e.g. feed type, loading order, outdoor temperature, block management, grabber retries, and grabber settings. For instance, loading accuracy can vary depending on the feed type; longer, more voluminous materials generally have a lower accuracy. It’s worth noting that straw or hay loading accuracy typically falls short compared to corn silage. To manage expectations and provide an idea of the average loading accuracy for each feed type, refer to the table below. These results are derived from 90% of the loading accuracy data, with extreme outliers excluded.

| Feed type (loaded by feed grabber) | Min-Max accuracy (%) |

|---|---|

| Grass | 78 – 95 |

| Corn | 86 – 98 |

| Straw | 62 – 94 |

| Hay | 69 – 95 |

| Vegetable/Fruit/Legume | 75 – 96 |

| Wet byproducts | 78 – 96 |

| Concentrate/grain | 58 – 95 |

| Loaded by auger | 95 |

Average grab size per feed type

The feed grabber allows for a 10% difference. So, if you require 10kg of straw, grabs between 9-11kg are acceptable. However, the grabber can’t detect amounts smaller than 2kg. Consequently, for a 10kg request, grabs between 8 and 12 kg are accepted. It’s vital to understand that small quantities can appear significantly different in percentage terms. For example, in a bin with only 5kg of straw, a difference of 1.5kg equals a 30% variation. Therefore, it’s crucial to consider the average grab size. When preparing a ration, always evaluate the impact per feed type within the bin.

| Feed type | Average grab size (kg) |

|---|---|

| Grass | 27 |

| Corn | 29 |

| Straw | 5 |

| Hay | 8.5 |

| Vegetable/Fruit/Legume | 26.5 |

| Wet byproducts | 26 |

| Concentrate/Grain | 16 |

Tips on how to manage your loading accuracy

Be realistic based on the type of feedstuffsMake sure that the correct feedstuff is in the right storage place as shown in HorizonUse the correct feed grabber setting for each feedstuffPlay with the retries. Allow more retries if the feed stuffs tend to be less accurateThe distance between the top of a block and the feed grabber should never be less than 1 meterTake into account the time needed to warm up the oilKnow that the loading order can have an influence on your accuracyHave a good kitchen management: block placement, clean up feed scrapsContact the technician if the calibration is not goodAlways contact your local FMS advisor when changing settings and check what the system doesNever change more than 1 or 2 settings at the same time if you want to know which change had an influence (positive or negative)