Milk Quality Control (MQC)

The Lely MQC-II (Milk Quality Control) is part of the robot arm, situated alongside the udder when milking. One of the main aims of the MQC-II is to act as a second pair of eyes, to see non-consumable milk and to separate it. During milking, the milk is permanently monitored for every quarter individually. This provides the farmer with vital information about mastitis, fat and protein percentages, blood in the milk, colostrum and lactose. The milk quality and health of the cow can be controlled with this information; you can act quickly and guarantee optimum milk quality. This will result in lower treatment costs and no production loss throughout the lactation period.

The following parameters are monitored in real-time during milking: milk colour, conductivity, milk time, dead milk time, milk speed and temperature. This continuous insight into milk quality, cow health and milk performance status will help you make better farm management decisions.

MQC-II is responsible for a fluid milking process and responds directly to changes in the milk and airflow. This means cups are taken off individually at the correct moment and that teat cups are reattached quickly if the udder is not empty.

MQC fat and protein indication

The MQC2 does not measure the actual fat and protein % in the milk, but provides an indication of their levels. All cows have their own genetically determined range of smaller or larger fat globules. The light used in the MQC2 to calculate fat and protein indications corresponds to a certain fat globule size. Readings from the MQC2 may differs from a lab analysis, however, the actual trend in fat content changes during lactation is still perfectly shown by the MQC.

KPI for fat, protein and the fat/protein ratio

Protein =average protein indication of the herd. Clicking on the KPI opens additional information and reports (Milking-herd overview and Milking-individual cow data). Fat = average fat indication of the herd. Clicking on the KPI opens additional information and reports (Milking-herd overview and Milking-individual cow data). Fat/protein ratio = indication of economic efficiency and general health. Should be between 1 and 1.5. A ratio of <1 indicates acidosis; a ratio of >1.5 indicates ketosis. Clicking on the KPI opens additional information and reports/graphs (Milking-herd overview and Milking-individual cow data). Calculation method Individual fat and protein indications are available as an average of the last 5 milkings. Herd averages are calculated from the individual cow data for the last milking.

Calibration

To ensure reliable calibration, Lely advises a minimum of 90 milk samples per milking robot (more than one sample per cow can be taken). If fewer than 60 milk samples per milking robot are taken, calibration cannot be completed and the fat and protein indications will not be shown.

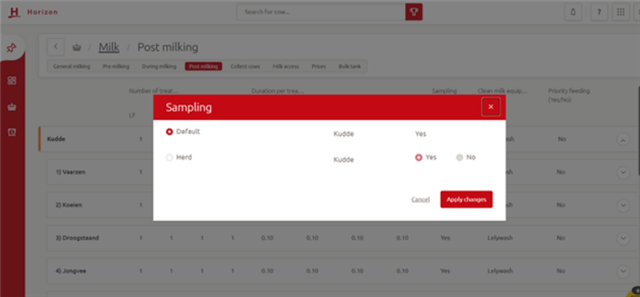

Activate milk sampling

Click on Manage -> Milk -> Post milking -> select the main herd in the column Sampling (Yes/No) -> Select Herd Yes to enable milk sampling –> Apply changes.

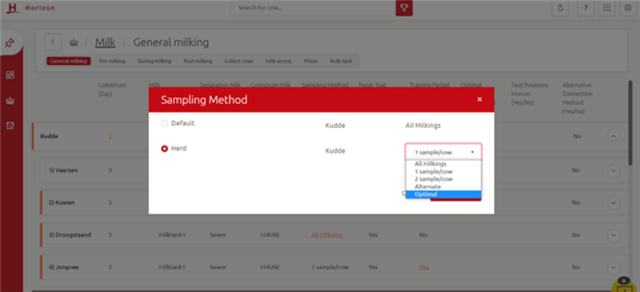

Set the Sampling Method

Click on Manage -> Milk -> General milking -> select the main herd in the column Sampling Method -> Choose either option sample/cow or option optimal.

With the sample/cow option, every cow is sampled for two consecutive milkings.

With the optimal option, every milking of a cow is sampled within a set period. Cows milked outside this period are sampled once. The period, in hours, is set in the column Optimal Sampling Period.

MQC sensor replacement

When one or two sensors on the MQC need to be replaced, the system will use the two or three remaining sensors to calibrate the new quarter sensors automatically. This will require 500 milkings, during which the fat and protein results are calculated by the sensors that were kept in place. After these 500 milkings, the new sensors are calibrated, and the fat and protein indications are shown at cow level again.

When more than three sensors, or a complete MQC, are replaced, a new calibration is required.

Note: avoid changing MQC-2 sensors during a milk sampling for calibration.

If a sensor change is necessary, make sure this is done 5 days prior to the sampling. If a sensor is changed during sampling for calibration, the calibration cannot be performed, and a new sampling and calibration will be necessary.